Preparation & Planning

According to FAR 91.407(b) an operational check flight is required any time an aircraft has undergone maintenance “in a manner that may have appreciably changed its flight characteristics or substantially affected its operation in flight.” While this is open for interpretation I approached my first flight in 21P as an operational check flight. To re-cap: we had all the control surfaces off, wings off, prop repaired, new avionics, and a recalculated weight and balance. In my mind those things certainly could affect flight operations. It is important to remember that an operational check flight can only be conducted on an airplane that has been properly returned to service in airworthy condition. It cannot be used to determine airworthiness.

I started with a detailed written inspection plan for the major areas we had apart. I chose to do three checks. One by me and two by other mechanics that had not worked on the plane. Here is the checklist I used to check the re-assembly. One of my main concerns was correct flight control movement and rigging. More than one aircraft has been lost due to a mechanic improperly rigging a control surface. Piper found this to be a significant enough issue that they include several statement in bold red text in the service manual section on rigging. I consolidated them in this document as an addendum to my check list.

After we were satisfied with the re-assembly we re-installed all of the inspection panels, cover plates and interior parts. With the airplane buttoned up I did a final check of panels, control surfaces, and one final gear swing. At this point I was ready for high speed taxi tests. During high speed taxi I paid particular attention to engine instrumentation and overall feel of the airplane. With engine instrumentation and handling satisfactorily I was ready for the first flight.

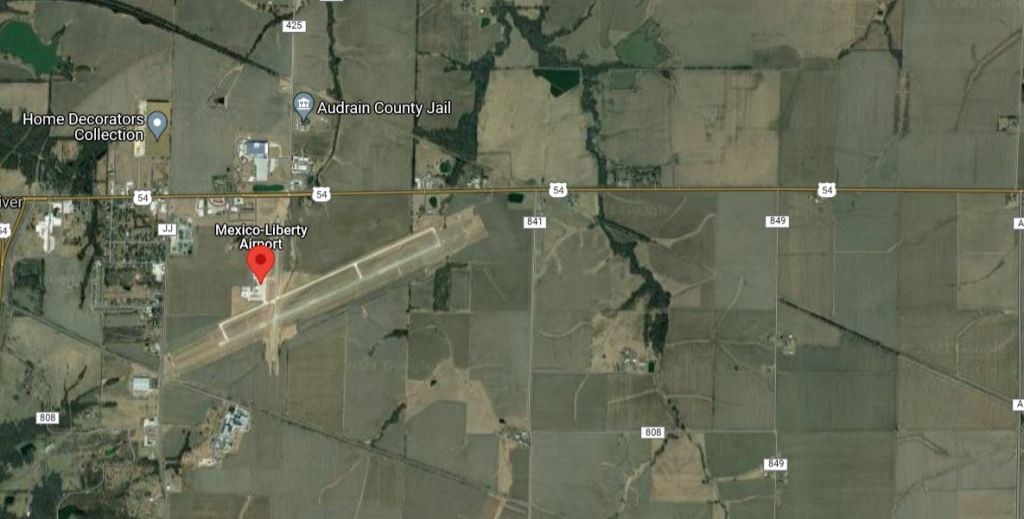

The operational flight check should be conducted under day VFR conditions with no passengers and minimal distractions. I also add a calm wind condition and a minimal traffic condition. I delayed my flight a week due to a local fly-in on account of traffic at the airport. Also for consideration is emergency landing zones to deal with an engine failure on take off scenario. Luckily our airport in Mexico Missouri (KMYJ) is surrounded by thousands of acres of Corn, Soybeans, and Wheat fields. Three of our four runways have excellent choice for an emergency landing immediately following departure. My preferred runway is 24 with more than adequate options immediately to the east of the field for emergencies. The planning for emergencies is the most important part of the flight check as it puts you in the correct “test pilot” mind set.

The final step prior to the check flight was to plan the flight profile. Mine looked like this: normal take off, climb out at Vy to 3500 feet and circle 3 miles to the south east end of runway 24. While circling (flying a box pattern) south east of the field I would check power settings at 55%, 65%, and 75% and compare with book power settings. While flying the box at these power settings I would check rudder and aileron trim and the ability to trim the plane to a hands off straight and level state. Return to the airport would be a simple 45 degree entry to the down wind for 24 and full stop landing.

So thats the plan. Next up how it went.