We left off with a complete lack of propeller pitch control during our run up and taxi Memorial Day weekend. The short version of the below story is that we need new clamps for our prop or a different prop. This was a challenging problem to diagnose and here is how we did it.

More often than not, a lack of pitch control is caused by a lack of oil control to the prop. The Hartzell HC-92ZK-8D propeller is controlled by increasing oil pressure to the prop thereby increasing the blade angle. This means the propeller governor must take the engine oil supply and increase its pressure to around 275 PSI to operate the pitch change mechanism. Our Woodward 210185 propeller governor had just been overhauled, but after discovering we had no prop pitch we sent it back for another bench test, which it passed with no issue. Aircraft Accessories of Oklahoma was very helpful with the bench test and also provided me with the technical data to do an on aircraft test of the oil pressure output of the governor. While the governor was being bench checked I performed Lycoming SI-1462A Prop Oil Control Leak Test. This test involves installing a ported plate in place of the governor and checking first the engine oil pressure to the governor then applying compressed air to the prop oil control circuit through a differential pressure tester (engine compression guage) and checking for correct pressure. Both of these tests were with-in Lycoming’s specifications. When the governor arrived back from Oklahoma I installed it and did an on aircraft pressure test. There is no approved procedure for this but I fabricated a test set and did a ground run to check the discharge pressure of the governor. It was right on specification in the Woodward Overhaul manual. Pictures of my test set below.

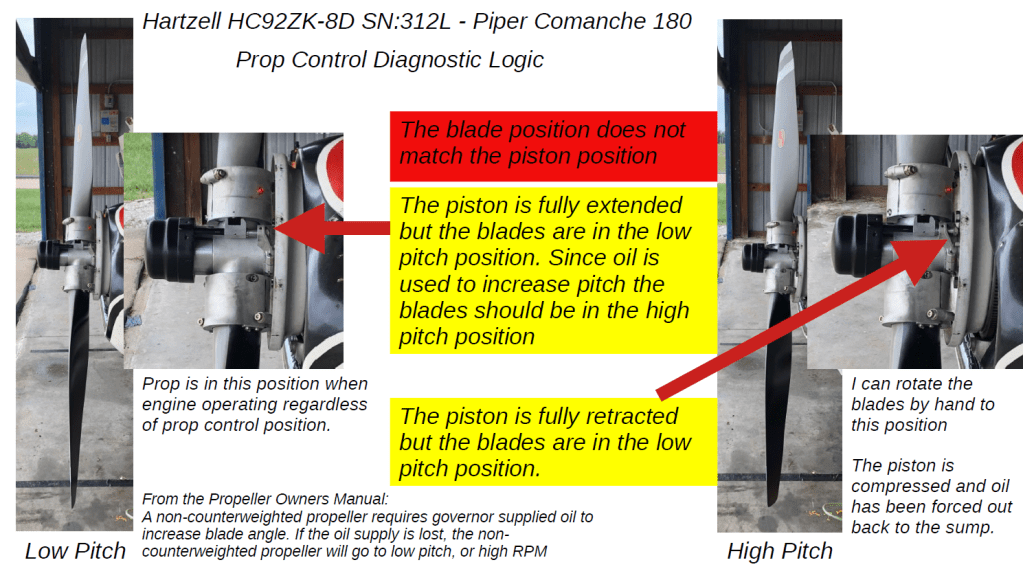

At this point I was out of ideas and had my in house parts technician (my super wife) reach out to Harztell for some help. They suggested a rehash of everything I had already done. I double checked everything just to make sure I didn’t miss anything the first go around. I didn’t. Everything was in accordance with the appropriate specification. I thought about it for a few days and came up with a trouble shooting document to share with our propeller shop and Hartzell. I was pretty sure the prop was the issue. Below are some images from the document. You can down load the PDF here.

As you can see from the above picture the blade position does not match the position of the piston. We sent this to Hartzell and our prop shop for review. Both concurred that something was not right with the prop. Hartzell product support was extremely helpful in providing technical documents and researching by serial number propeller components. After some pretty exhaustive research Hartzell determined the blade clamps were incorrect for the propeller despite being marked with the correct part numbers. We suspect these clamps were put on when the propeller was overhauled in 2010 just before installation on N6211P. I also suspect that this is a major reason 21P languished for so many years as this was such a difficult problem to solve.

Bottom line we need blade clamps for a HC-92ZK-8D prop or a different prop.